Additional Information

| Financing | Available |

|---|

DISCLAIMER: Price quoted does not include any freight or delivery charges. Specifications are believed to be correct but may contain errors and/or omissions. Pictures are representative and may not be identical. Description and Images © West-Mark

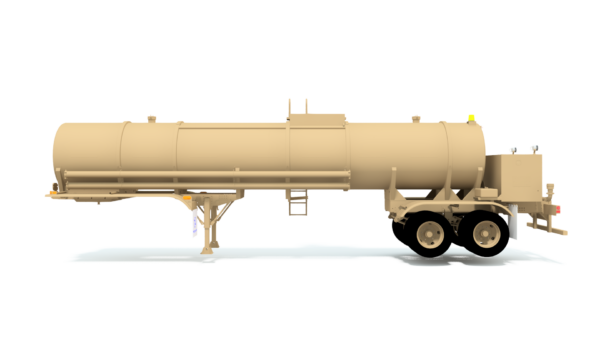

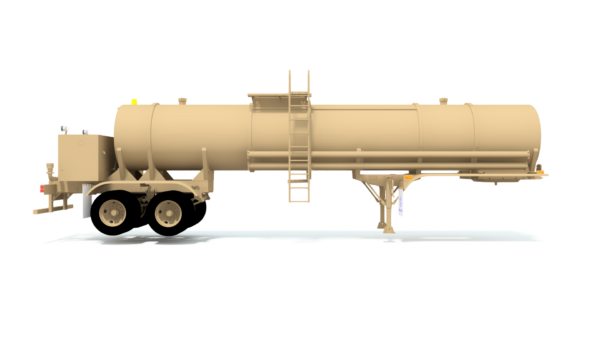

5,000 Gallon Non-Potable Tandem Axle Semi Trailer (500TASPRA)

Water storage and transport made simple with the West-Mark 5000TASPRA. These units are crafted for water distribution and is perfect for on-base operations to carry and distribute sizable amounts of potable water/ non-potable, or non-hazardous liquids.

GENERAL

The following equipment shall be a new West-Mark tandem axle semi trailer.

OVERALL LENGTH: Approximately thirty-eight feet six inches (38′ 6”).

PRODUCT: Non-potable water.

PRODUCT WEIGHT: 8.35 lbs./gallon.

VESSEL CODE: Non-Spec.

TANK OPERATING PRESSURE: Atmosphere.

VACUUM RATING: None (0 in./Hg).

OPERATING TEMPERATURE: 165° F maximum.

INTENDED AREA OF OPERATION: Specify _______________________________.

INTENDED USE: Highway and Off-Road.

TRACTOR

- Tractor, Customer supplied.

TANK/ MANHOLES/ VENTING

- Barrel, 5000 Gallons T-304L stainless steel 10GA round, straight.

- Capacity does not include head outage.

- Heads, 12GA stainless steel, dished and flanged.

- Baffle(s), two (2) 10GA stainless steel, dished and flanged.

- Rings, stainless steel channel sections, fully welded to shell (if required).

- Stiffener, backbone welded to shell.

- Wings and Bolsters, Stainless Steel.

- Side Filler, Stainless steel.

- Weld Finish, interior to be W-2 with all longitudinal seams to be W-3. Exterior weld finish to be W-2.

- Manhole(s), one (1) 20″ stainless steel full opening with White Hypalon gasket.

- Venting, one (1) 1-1/2″ pipe installed in collar of manhole down side of tank with ball valve at bottom.

- Vent, one (1) Fill Cap, sanitary stainless steel style with a flip up fill cap.

- Sight Gauge(s), one (1) acrylic liquid level gauge sight tube assembly with shutoff valve and drain cock at bottom. Red ball installed inside tube. Gauge to be located at rear head.

- Passivation performed on interior of tank per ASTM A967.

LADDERS/ WALKWAYS/ SPILLDAMS

- Spilldam, one (1) non-insulated, stainless steel box style with drains.

- Ladder, one (1) aluminum multi-purpose.

- Walkway, aluminum non-slip platform at side of spilldam.

LIGHTS AND WIRING

- Electrical System 12-volt, 7-way, and vapor proof. Lamps to be L.E.D. and meet all D.O.T. requirements

– Four (4) stop/tail/turn lights in 2-hole, stainless steel boxes; 2 red each side.

– One (1) red 3-light I.D. at rear

– One (1) amber turn/marker light @ center of unit (prox.) each side if required by DOT.

– One (1) amber marker light each side of unit at front.

– One (1) red marker light each side of unit at rear.

- Back-up alarm.

- Reflectors, per D.O.T.

- Conspicuity Striping, per D.O.T.

- Front Receptacle, 7-way nosebox w/ 15 amp circuit breakers.

- Worklight(s), two (2) halogen with switch.

- Warning Beacon(s), one (1) revolving yellow halogen.

- Rear Outlet, stainless steel split pipe to a 3″ butterfly valve.

- Plumbing to end in 3″ stainless steel male camlock adapter and lockable brass cap with chain.

- Hydrant Fill, with dual check valves.

- Hydrant Fill Connection, one (1) 3″ stainless steel male Camlock adapter with cap and chain.

PUMPING

- Discharge Plumbing, stainless steel connecting tank outlet to rear manifold for the following functions:

– Gravity unload through 3″ outlet.

– Pump water in and out of tank through 3″ outlet.

– Pump water to rear mounted spray heads

– Pump water to hose reel. Victaulic couplings and rubber hose used in plumbing as needed.

- Flow Diagram shall be affixed near plumbing to assist the operator with the operation of each valve for each plumbing function. Valves shall have I.D. tags to correspond with Flow Chart. All diagrams and I.D. tags shall be made of non-ferrous metal (no plastic).

- Rear Spray Head Package, two (2) fully adjustable grooved nozzle spray heads on a stainless steel distribution bar.

- Electric Receptacle at Front of Trailer, wired to electric-over-air solenoid(s) to operate sprayhead(s), beacon B/U alarm, and B/U lights when specified.

- Auxiliary Switches Kit for Tractor, one (1) for wiring trailer’s back-up alarm/lights, sprayhead(s), beacons, etc. to tractor. (Shipped loose for customer to install on tractor.)

- Hose Reel(s), one (1) spring rewind.

- Delivery Hose(s), one (1) 1″ x 50′ water with stainless steel male NPT ends.

- Nozzle(s), one (1) 1″ adjustable thermoplastic spray.

- Hose Reel Plumbing, stainless steel with s/s ball valve inline shut-off. Rubber hose used as required.

- Cabinet(s), one (1) stainless steel non- insulated double door (approx. dimensions) with stainless steel hardware and lockable latch located at rear.

- Cabinet Dome Light, two (2) L.E.D. with switch.

- Pump and engine assembly, one (1) with electric start diesel engine; rated at 250 GPM (min)

- Fuel Tank, To be remotely mounted in an easy access location for tank fill.

- Battery(ies), one (1) in plastic enclosure.

UNDERCARRIAGE

- Kick Plate, stainless steel.

- King Pin Plate, adjustable carbon steel upper coupler set at a 48″ ride height.

- Landing Gear Subframe, stainless steel.

- Landing Leg Support, pipe style.

- Extra pipe supports for bracing at landing legs.

- Landing Gear, 2-speed, steel, with sand shoes.

- Rear Subframe, stainless steel construction for a tandem axle suspension; extended for rear pumping system.

- Rear Cover, stainless steel between bumper uprights

- Suspension, one (1) with cast hangers for tandem axle.

- Spring(s), four (4) 3-leaf medium arch.

- Axle(s), two (2) 71-1/2″ track, hub piloted, with auto slack adjusters.

- Outer Wheel(s), four (4) steel painted.

- Inner Wheel(s), four (4) steel painted.

- Tire(s), eight (8) commercial grade radial.

- Brake System, to D.O.T. ABS system.

- Underidement Bumper, carbon steel if required by D.O.T.

- Front Fenders, aluminum contour.

- Fender Pipe Mounting, stainless steel with U-bolts and under straps.

- Mudflaps, black rubber.

- Rear Fenders, aluminum contour.

- Fender Pipe Mounting, stainless steel with U-bolts and under straps.

- Mudflaps, black rubber.

MISC.

- Hose(s), four (4) 3″ x 20′

- Transport Security System, lugs for padlock/seal tab security system at all openings.

- Hose Tube(s), four (4) aluminum, with doors both ends.

- Paint, (specify color) all carbon steel fabricated parts.

- Decals shall be installed on each side of water tank.

- 4″ Decals to read: “NON POTABLE WATER”.

- 2″ Decals to read: “5000 GALLONS”

- One (1) Operation and maintenance manual(s) in paper format and one (1) on CD-ROM complete with:

– Operator & maintenance manual

– Calibration chart (if applicable)

– Equipment parts list

– Misc. vendor literature / manuals

- Theoretical calibration chart shall be supplied

- Vehicle shall be road tested.

Any and all Brand Name parts mentioned in specifications above are subject to substitution of an equal part that is of a different brand. Other substitutions may also be made if said substitution does not affect the intended function of the vehicle’s mission and is equivalent or an upgrade as determined by West-Mark. All specified dimensions are nominal and may vary slightly.

F.O.B.:

West-Mark (CAGE: 880W5)

581 Industry Way

Atwater, CA 95301. (F.O.B. destination available as option upon request.)